The scenario

December 12, 2015, was a historical day: world leaders recognized the urgency of climate change and signed the Paris Agreement, committing to reduce carbon emissions and limit the average global temperature rise by 1.5 degrees Celsius. But to what extent is the legally binding international treaty making history? Scientists have warned about the threat for decades, prompting policymakers, investors, and public opinion to grow increasingly aware and proactive. When it comes to the green transition, there seems to be a disconnect between what we need to do and what we are doing.

2020

2030

2030

36.7 Gigatons

of CO2per year

0.58%

percentage of EVsvs total road stock

Will we manage to manufacture

200 million new EVs by 2030?

What about the impact?

How to meet governmental goals and deadlines?

Public transport, especially buses, is the primary cause of pollution in big cities and densely populated areas. Up to recently, the trend has been to resort to manufacturing new electric vehicles, with the supply chain unable to keep up with the ever-increasing demand. But now, everyone (central governments and local administrations, manufacturers, and public opinion alike) is realizing that’s not enough. From the difficulties of sourcing batteries to increased gas emissions, manufacturing new EVs remains cost- and result-inefficient. Repurposing retired vehicles proves to be a quicker, smoother, and greener midterm solution.

Manufacturing alone won’t drive us to 2030.

What about repurposing?

-

01

We start

with large urban fleetsThere’s strength in numbers, and more impact: we study a car or bus platform at a time and repurpose entire fleets of the same model.

-

02

We save

unwanted vehiclesScrapping retired ICE vehicles increases gas emissions and overall costs. Conversely, repurposing treads lighter on the environment as it avoids scrapping.

-

03

We re-engineer

themRepurposing is more performative than retrofitting in that it re-engineers the whole vehicle and systems instead of single parts, thus ensuring performance and safety.

The issues we are addressing

Short-to-mid-term, putting new electric vehicles on the road poses a series of overlooked questions about cost-efficiency, sustainability and pollution, and sourcing timing that slow down the green transition.

-

Manifacturing issue

30%

of total costBatteries are a necessary cost, the rest is not

Manufacturing, body, and interior work account for 30% of the total cost of a new EV, sensibly increasing the cost and end-price compared to a repurposed vehicle.

-

Enviromental issue

27%

added carbonThe gas emissions

from producing new

EVs are highEvery new EV manufactured and sold adds 27% carbon dioxide into the atmosphere, from producing the new chassis and body to the final assembly and distribution.

-

Timing issue

42%

required growthThere are not enough plants to build enough new EVs

Manufacturers cannot produce as much as we’d need. To meet the 2030 Agenda production should ramp up by 42% year-on-year, but the expected growth halts at 25%.

Our horizon

We keep the wheels of mobility turning to accelerate the electric transition. We are partners in expanding knowledge to build concrete solutions for the planet.

Petrol-to-electric

is just the first step

The future of mobility lies in data. Large-scale public transportation fleets are the perfect platform to gather as much information as possible and enable reliable and safe autonomous systems. In a midterm scenario, we plan to fit all of our fleets with autonomous systems, to promote the transition towards a shared autonomous sustainable mobility ecosystem.

Transforming mobility

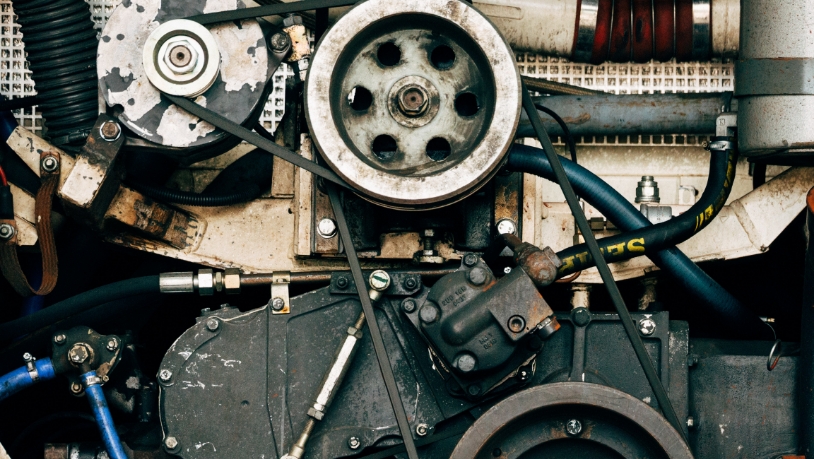

Petrol engine

Internal combustion engines have powered our cars for over a century but are now living on borrowed time under the threat of taxes, legislation, and customer preference. Gradually but steadily, petrol engines will be unable to meet national and international emissions standards, becoming increasingly unappealing to the general audience worldwide.

Electrified engine

To decarbonize the automotive industry manufacturing new EVs from scratch is widely the preferred solution. But with battery tech and fuel cells remaining expensive and the gas emissions produced by scrapping unused ICE, we need a complementary, alternative solution. That is where repurposing petrol engines to electric proves advantageous in terms of costs, efficiency, and feasibility.

Autonomous fleet

Technology and the IoT continue to redesign how we get around and shape the future of mobility — one with self-driving vehicles. From advanced sensor technology to smart control systems and intelligent actuators, it’s not just automated vehicles being able to set themselves in motion but enhancing safety through communication between them and the surrounding infrastructure.